Dr. Joy Ebben Addresses Carpal Tunnel Syndrome

By Joy M. Ebben, Ph.D, CPE

Human Factors and Ergonomic Specialist, IAC, a Division of Treston, Goodyear, Arizona

In the April issue of Occupational Health & Safety magazine, an article authored by Dr. Joy Ebben discusses symptoms, causes, and treatment for carpal tunnel injuries suffered in the industrial workplace.

In “It’s Not Just With Keyboards, “ Dr. Ebben relates how long scars on the wrist of a bellhop helping with her luggage led her to surmise correctly that he had undergone carpal tunnel surgery. He had incurred his injuries on an assembly line job, where although the parts he handled were not heavy, he used physical force to snap them into place at a work pace set by a conveyor belt. Thus, the job involved repetitive forces an awkward postures – thought to be among the major contributors to carpal tunnel syndrome (CTS) injuries.

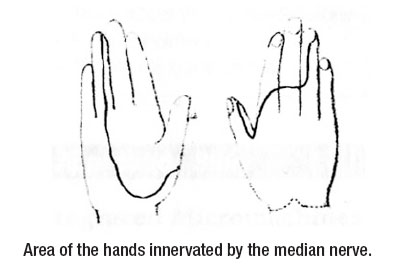

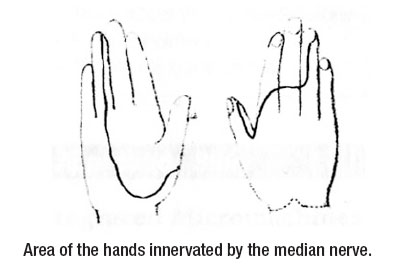

As Dr. Ebben’s article explains, CTS is a nerve entrapment disorder that takes its name from the “carpal” bones of the wrist. The tendons that control finger flexion and the median nerve, one of three nerves that transmit motor and sensory impulses from the hand to the central nervous system, pass through a tunnel formed in each wrist. Compression of this nerve causes the numbness, tingling and discomfort that are the symptoms of CTS.

In the following excerpt from her article, Dr. Ebben offers specific recommendations for eliminating or reducing CTS risks factors in an industrial workplace:

In the following excerpt from her article, Dr. Ebben offers specific recommendations for eliminating or reducing CTS risks factors in an industrial workplace:

- A few workstation design characteristics can have a significant impact on reducing the risks of CTS during high repetition of awkward postures, especially when exerting force.

- Provide the correct working height for repetitive task performance. Having he work surface height either too height or too low can lead to the selection of an awkward posture of the wrist while performing tasks.

- Angle parts cups so when parts are repeatedly retrieved, the wrist is allowed to stay in a neutral posture.

- Provide features so assemblies can be easily positioned to allow repetitive forceful job tasks to be performed with neutral wrist postures and less force.

- Provide holding fixtures so parts do not have to be held in place when being work on, reducing force and awkward postures.

- Provide appropriate lighting to make product inspection possible without having to manually manipulate a surface, reducing force and awkward wrist postures.

The good news is that workers comp, lost workdays, and other costs related to CTS – one of the more expensive illnesses in the workplace – seem to be declining. The trade magazine CTD News reported a 45% decrease in CTS direct costs from 1996 ($4,764 per case) to 1998 ($2,126 per case) in industry and office environments.

“CTS is often preventable,” Dr. Ebben sums up. “Try to keep your wrists in a neutral posture, use tools and techniques that minimize required force, have a proper working surface height, design and arrange your work space to minimize the CTS risk factors, and make sure to have enough breaks to have sufficient recovery time.”

The article addresses CTS causes and prevention in detail. If you have a customer with an interest in this particular workplace injury, look for the complete article in the April issue of Occupational Health & Safety.

Buy Online Now!

Buy Online Now!

Buy Online Now!

Buy Online Now!

In the following excerpt from her article, Dr. Ebben offers specific recommendations for eliminating or reducing CTS risks factors in an industrial workplace:

In the following excerpt from her article, Dr. Ebben offers specific recommendations for eliminating or reducing CTS risks factors in an industrial workplace: