ESD Protection

Built-in safety devices for electrostatic discharge (ESD) control are available for IAC industrial workbenches and carts on which static sensitive electronics components are assembled, tested, and transported.

IAC ESD industrial workbenches include the following:

- Rounded edges on worksurfaces. A rolled front edge (180°), featured on IAC premium and industrial workbenches, protects against lifting, chipping and other damage to the ESD-safe laminate at a sharp-edged seam.

- Static-dissipative laminates on worksurfaces and shelves – IAC uses two (3M and Nevamar®).

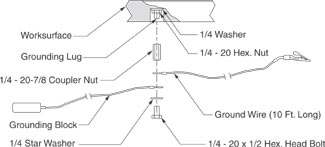

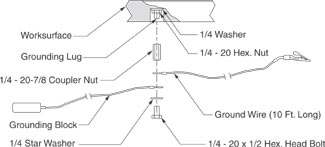

- Stainless steel ESD grounding lugs built into the worksurface.

- Optional personnel grounding wrist straps and ground blocks.

Typical IAC Grounding Components

See how we pre-install ESD grounding bolts on ESD benches

ESD Testing

All IAC static-dissipative worksurfaces, shelves and ground bolts are pre-tested at the factory.

Using a megohmmeter the surface resistance should measure between 1 megohmm (106) and 1,000 megohms (109) at 50% relative humidity. At 10% relative humidity, resistance increases one order in magnitude 1x 1010 at 90% relative humidity or higher, resistance decreases one order in magnitude 1x 105. IAC uses a 3M Model 701 Megohmmeter.

Using a multi-meter perform a standard continuity test between the ground stud that is connected to the laminate of the worksurface or shelf and end of the ground cord. The resistance should measure approximately 1 megohm. Note: The IAC worksurface ground cord include a 1 megohm resistor built in.

Buy Online Now!

Buy Online Now!

Buy Online Now!

Buy Online Now!